remove, then remove the brake band lever. Do not remove the brake band as it will be used in lifting the steering clutch and brake drum assembly.

7. Remove the capscrews attaching the steering

clutch assembly to the driving hub and the

brake drum hub. This will necessitate turn-

ing the clutch assembly and brake drum

which can be accomplished by inserting a

suitable bar in one of the ventilating holes

in the brake drum.

clutch assembly to the driving hub and the

brake drum hub. This will necessitate turn-

ing the clutch assembly and brake drum

which can be accomplished by inserting a

suitable bar in one of the ventilating holes

in the brake drum.

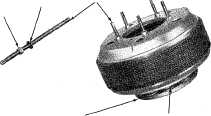

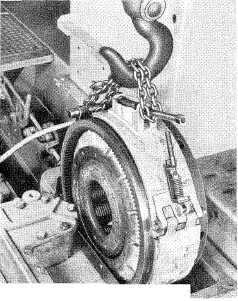

8. Using a chain hooked around the brake band

adjuster and around a yoke pin placed in

the lower end of the band, lift the steering

clutch assembly and brake drum out of the

compartment as shown in Figure No. 1.

adjuster and around a yoke pin placed in

the lower end of the band, lift the steering

clutch assembly and brake drum out of the

compartment as shown in Figure No. 1.

from the top of the housing and pour about three gallons of solvent into each compartment. Drive the tractor back and forth in a straight line for approximately five minutes, leaving the steering clutches engaged. The oil on the exterior of the clutches and brakes will be washed off in this operation.

3. Drain the compartments and refill with the

same amount of solvent, then drive the trac-

tor back and forth for approximately another

five minutes, disengaging one clutch and

then the other continually during this period.

Disengaging the clutches allows the clutch

discs to separate so that the solvent can get

in between the discs to wash the oil from

their friction surfaces.

same amount of solvent, then drive the trac-

tor back and forth for approximately another

five minutes, disengaging one clutch and

then the other continually during this period.

Disengaging the clutches allows the clutch

discs to separate so that the solvent can get

in between the discs to wash the oil from

their friction surfaces.

4. Drain the compartments and allow the

clutches a short time to dry. Operate the

tractor with a light load in low gear until

the clutches become thoroughly dry, other-

wise they may slip due to the presence of

solvent on the discs.

clutches a short time to dry. Operate the

tractor with a light load in low gear until

the clutches become thoroughly dry, other-

wise they may slip due to the presence of

solvent on the discs.

ID. Clutch Removal.

1. Remove the fuel tank (refer to "FUEL TANK

REMOVAL" in Section II).

REMOVAL" in Section II).

2. Remove the center and rear floor plates.

3. Remove the jam nut, and the brake band

support adjusting nut.

support adjusting nut.

4. Remove the steering clutch compartment

covers.

covers.

5. Turn the brake band adjuster counter-clock-

wise untii it is loosened from the brake band

adjusting fork.

wise untii it is loosened from the brake band

adjusting fork.

6. Remove the yoke pin connecting the brake

rod yoke assembly to the brake band lever.

Remove the pipe plug located in the side of

the steering clutch case in line with the brake

band pin, and using a suitable 3/8" N.C.

capscrew inserted through the hole, turn it

into the tapped hole in the end of the pin.

Now pull the brake band adjusting fork pin

out and remove the brake band adjusting

fork. Lift up on the brake band lever until

the pin attaching the lower end of the band

to the lever, can be removed. Push the pin

towards the bevel gear compartment and

rod yoke assembly to the brake band lever.

Remove the pipe plug located in the side of

the steering clutch case in line with the brake

band pin, and using a suitable 3/8" N.C.

capscrew inserted through the hole, turn it

into the tapped hole in the end of the pin.

Now pull the brake band adjusting fork pin

out and remove the brake band adjusting

fork. Lift up on the brake band lever until

the pin attaching the lower end of the band

to the lever, can be removed. Push the pin

towards the bevel gear compartment and

Vtl __ ..

Fig. 1—Removing Steering Clutch

I. Disassembly of Steering Clutches.

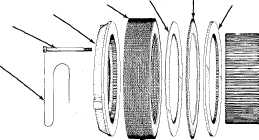

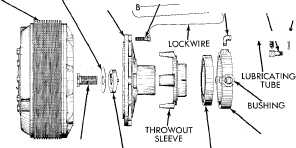

1, Remove the drum from the clutch assembly

being careful not to bend the clutch disc

teeth.

being careful not to bend the clutch disc

teeth.

2. Before disassembling the clutch, center punch

the pressure plate, the back plate, the hub,

and the throwout plate so that they can be

reassembled in the same position as they

were before disassembly.

the pressure plate, the back plate, the hub,

and the throwout plate so that they can be

reassembled in the same position as they

were before disassembly.

199